Key features to look for in a stretch wrapping machine

Key features to look for in a stretch wrapping machine

Blog Article

Discover the Conveniences of Using a stretch wrapping machine for Reliable Product Packaging Solutions

Automation has actually brought forth considerable developments, such as the stretch wrapping machine. What makes these devices a game-changer in the product packaging market?

Comprehending the Functionality of Stretch Wrapping Machines

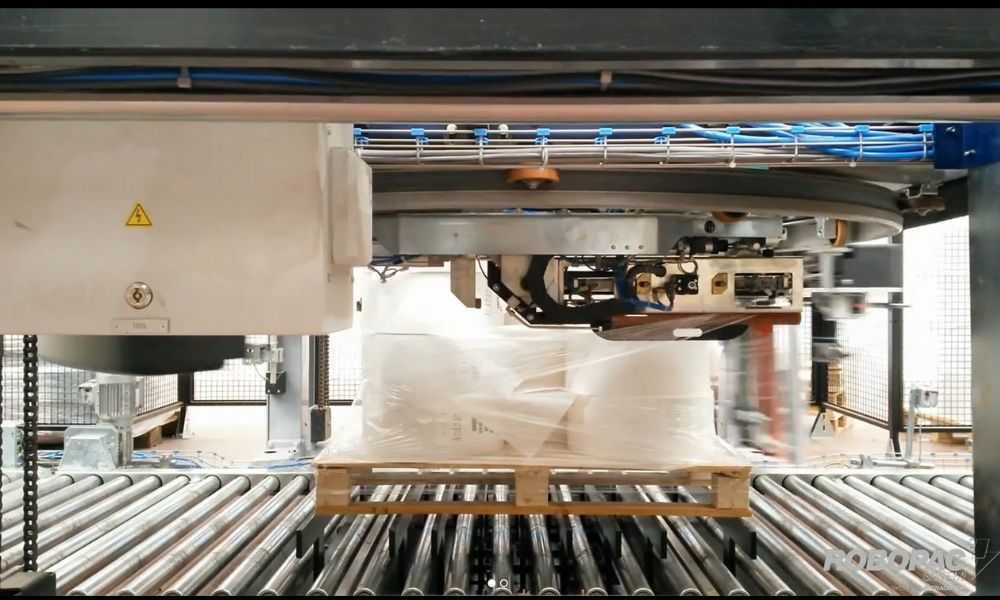

Spearheading the packaging sector, stretch covering equipments enhance the process of firmly packaging products for transport or storage. These advanced equipments utilize a simple yet reliable mechanism, making use of a stretchable plastic movie that is wrapped around products, offering stability and defense. The items, frequently set up on a pallet, are rotated as the movie is dispensed, guaranteeing a protected and tight cover.

The movie's flexibility offers a double function: it tightly binds the products together, reducing the risk of damages as a result of activity, and it provides a barrier versus dust, dampness, and other prospective unsafe elements. Furthermore, the clear nature of the stretch movie enables simple identification of the packaged items.

The makers differ in their operation setting, with some being semi-automatic, requiring very little human intervention, and others being fully automatic, capable of separately managing the entire wrapping procedure. Despite their setting, stretch covering machines are a foundation of safe and effective product packaging.

Exactly How Stretch Covering Machines Enhance Productivity

Increasing performance levels significantly, stretch covering devices enhance the packaging process with their automated abilities. These sophisticated machines allow companies to wrap a high quantity of bundles rapidly and successfully, supplying a constant covering outcome that manual methods merely can not match. This speed and consistency convert directly into enhanced performance, enabling companies to fulfill demanding supply timetables and customer assumptions.

Additionally, stretch covering makers require marginal human intervention. As soon as the equipment is set up and the covering specifications are configured, the maker can operate individually, liberating staff members to focus on various other important tasks. This automation not just lowers labor prices but likewise removes human mistakes, making sure the high quality of covering stays regular.

Furthermore, making use of stretch wrapping equipments commonly leads to less downtime. stretch wrapping machine. With their durable design and reputable procedure, these machines are much less vulnerable to break downs and maintenance issues, ensuring nonstop workflow and enhanced performance

Decreasing Material Waste With Stretch Covering Machines

While improving productivity, stretch covering equipments likewise play a vital duty in decreasing product waste. The precision of these devices makes certain that each plan is wrapped with the precise amount of product needed, reducing excess waste. This accuracy not just leads to a visually pleasing and regular bundle, but additionally adds considerably to environmental sustainability.

Fundamentally, the usage of stretch wrapping machines in a product packaging line is not only an action towards reliable performance, however additionally a jump towards green practices by considerably decreasing material waste.

Expense Decrease: A Trick Benefit of Stretch Wrapping Machines

In enhancement to mitigating product waste, one more considerable advantage of stretch wrapping devices is their possibility for cost reduction. These devices are reliable, needing much less hands-on labor for product packaging items, thereby reducing labor costs.

Additionally, stretch wrapping equipments make use of much less material to package goods safely as compared to standard covering approaches. This effective use materials not only decreases waste yet likewise lowers expense on product packaging products.

The equipments also decrease wikipedia reference damage to items throughout transport. With safe and durable packaging, the threat of product damages decreases, lowering the costs related to item returns and replacements.

Finally, the speed and efficiency of stretch covering devices can increase manufacturing rates. Faster packaging times mean that businesses can package and ship more items in much less time, boosting overall productivity.

Applying Stretch Covering Machines in Your Product Packaging Process

Given the impressive advantages of stretch wrapping makers, integrating them right into your product packaging process can be a game-changing decision. The execution procedure requires careful planning and training to make sure ideal application. An assessment of the current product packaging process is essential to identify the suitable equipment type and dimension (stretch wrapping machine). The selection must line up with the plan dimensions, weight, click here for more info and the volume of items to be covered daily.

Educating staff on device procedure is essential. This consists of understanding the maker's performances, troubleshooting typical problems, and adhering to safety guidelines. By doing so, companies can guarantee an efficient, affordable packaging process, reaping the complete benefits of their investment in stretch covering devices.

Conclusion

In verdict, stretch covering makers offer effective, affordable product packaging solutions. These makers ensure item stability and security, while also providing visually pleasing plans.

When the maker is set up and the covering criteria are set up, the maker can operate independently, freeing up staff members to focus on various other essential jobs.While improving efficiency, stretch wrapping machines also play an important role in reducing material waste.Given the impressive advantages of stretch covering equipments, integrating them right into your packaging procedure can be a game-changing choice - stretch wrapping machine. By doing so, services can guarantee an efficient, affordable product packaging process, reaping the complete benefits of their investment in stretch covering devices

In conclusion, stretch covering makers use efficient, cost-effective product packaging services.

Report this page